Grit blast before powder coating

Grit blasting cleans the metal and gives it a good key for the paint to adhere. It does not matter how good the paint is, applying it to dirty metal will result in the paint coating failing in the field. Windridge Coatings has two walk in grit blast bays:

- Bay 1, blast medium = Steel grit, capable of accommodating 10m x 1.0m x 2.7m high.

- Bay 2, blast medium = Aluminium oxide, capable of accommodating 5m x 2.5m x 2m.

Mill scale can look ideal to paint on

Although clean mill scale looks like a good surface to paint on, as most fabricators know it is very hard and brittle. When attempts are made to remove it by grinding or abrading, it is often left polished and shiny, which is unsuitable to paint on. Should the component suffer an impact the paint is likely to chip.

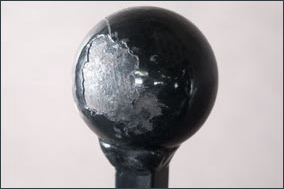

Mill scale chipped off taking paint with it

This is part of a chair powder coated by another trade coater. We were asked to strip and re-powder coat because it had chipped when it fell over. They had applied a thick coat of powder on the mill scale, which had chipped taking the paint with it. When powder coating is applied properly to a good key it can sustain a hammer blow. The paint will scratch but should not chip.

Caution should be used when dealing with a powder coating company that does not grit blast before painting over mild steel for architectural use.

All thick gauge steel is grit blasted

Windridge Coatings grit blasts all thick gauge steel to SA 2 1/2 (grey metal). This will produce an excellent key for the paint to adhere to. The finish will also be improved because mill scale being so hard chips leaving steps under the paint. Blasting will remove mill scale, rust and most contaminants. Abrasive blasting will also reduce light fabrication scratches and blemishes.