Spray paint a motorcycle by powder coating the frame

The best way to spray paint a motorcycles frame

With thousands of Internet searches a month ending at Windridge Coatings, we have become one of the best-known powder coaters for repainting the best motorbike frames. With meticulous attention to detail, we are able to achieve the quality finish previously only available with liquid paint. Blasting and powder coating is not the whole story this page will explain why.

Shown: Dec 1948 HRD Rapide B. When only the best is good enough.

Who should use Windridge Coatings?

Owners who do not want a quick cheap job, but those who need to be reassured their precious bike is going to be looked after and worked on with care and interest. Everybody admires a bike with a good paint finish. We are used when nothing less than the best quality is good enough. For perfectionists who rebuild their bikes to Concours d’Elegance standard.

Shown: 1914 Douglas, one of only three in existence. Once brown rust, now rebuilt to Concours standard.

The Tri-Resin™ System

An advantage of using an architectural powder is the depth of knowledge and facilities for protecting steel for at least fifteen years in all weathers. Coupled with a background of spraying quality cars, achieving a good finish for Windridge Coatings is second nature. The Tri-Resin System incorporates the best practices of corrosion inhibitors, liquid painting and powder coating. It is the way of the future for powder coating and your motorbike frame will look good and be better protected for it.

Powder coating looks good is tough and corrosion resistant

Not all bikes are gently ridden and spend most of their time being polished. Our powder coating is for hard-working bikes that need good corrosion protection and resistance to chip.

Click here for information about coating quad bikes and ATVs... more

But powder coating is not the original paint

Neither is two-pack polyurethane. All paints are made of pigment, resins and extenders. With wet painting, solvents are used to dissolve these into a liquid paint easy for application but with powder coating, there are no solvents; the heat is used to turn its ingredients into a liquid. When both are cured the average person would not be able to tell the difference between the two finishes. See below

How to present your frame for powder coating

Please present your frame with all brackets, fittings, bearings, grease and road dirt removed. Some modern bike frames are powder coated which is difficult to remove without damaging your frame with excessive blasting. To thoroughly clean your frame of existing paint and contaminants a controlled pyrolysis oven is used prior to blasting this will also remove any rubber or plastic left fitted.

Special colours not available in powder

If the bike requires a special colour unavailable in powder, many clients ask for the frame to be stripped, blasted and primed in powder. It can then be wet painted in two-pack polyurethane, acrylic, cellulose or many other types of wet paint. This has the advantages of the protective qualities of powder with the colours of wet paint.

What we do to your frame

The following will show the different stages of processing your frame will go through at Windridge Coatings. Gently removing paint and grease with controlled heat prior to blasting.

Removing paint and grease

The old paint and all grease need to be removed from the frame or it will spoil the new powder coating. Blasting alone cannot do this and any grease left, will run over the new paintwork when the frame is heated. The controlled pyrolysis process we offer is not used by many of our competitors. It is a special oven that carefully heats the frame to about 400 degrees Celsius to turn the paint, grease and any other contaminants into ash. Heating the component slowly and evenly avoids distortion.

Shown: Gently removing paint and grease with controlled heat prior to blasting.

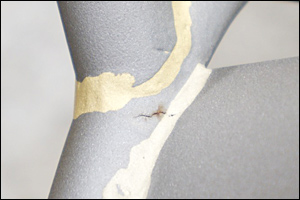

Pyrolisis semi anneals the frame to relieve internal stresses and reduces cracks

Heat treatment has another useful advantage with semi annealing the frame to reduce internal stresses accumulated by years of hard riding. The metal becomes work hardened, which leads to metal fatigue and is the cause of frame cracks. See below.

Grit blasting

To remove the ash Windridge Coatings grit blast motorbike frames. Grit blasting sometimes referred to as sandblasting or shot blasting removes the surface of the metal including rust. To reduce the amount of blasting so as not to weaken the frame we always remove paint first either by incineration or paint striping. Especially on modern frames that are often powder coated and is difficult to remove by blasting alone.

Shown: Grit blasting motorbike frame.

Corrosion inhibitor

To reduce the likely hood of the frame rusting under the paintwork a corrosion inhibitor is applied. This is an architectural metal pre-treatment process used to seal the metal after blasting. A concoction of chemicals passivates the metal combined with a low viscosity paint ensures no metal is left uncoated. Around brackets and the air pockets under the powder coat which can be the starting areas for undercoat rust creep. This is an expensive process that would not normally be used on motorbike frames.

Shown: Frame receiving anti-rust treatment.

Fatigue crack inspection

Grit blasted frames are checked for fatigue cracks prior to painting. The above image shows part of a TT sidecar that was condemned because we found a number of cracks throughout the frame, all of which would not have been seen without our inspection.

Shown: Frame flexing forms cracks due to work hardening.

Powder coat primer

Priming a motorcycle frame is very important, as it is the waterproof barrier. Polyester powder coat on its own is not sufficient protection on steel against corrosion. The primer is expensive and most powder coaters will leave out this stage because the customer cannot see it. Not only will it prolong the life of the frame against rust but it also produces a smoother finish. A knowledgeable powder coater must apply the primer or the paint will be prone to cracking. To avoid the frame number being lost Windridge Coatings masks the serial number at the primer stage. Depending on how prominent the number is we may not powder coat over it all but lightly wet paint.

Shown: Powder coat primer protects against corrosion.

Perfect paint finish

We use one of the most expensive black powders on the market to give you the deepest glossiest black. Treat it like any other paint, wash, compound and wax and it will last for decades.

Shown: When only the best is good enough.

Powder coat testing

Windridge Coatings often gives talks to bike clubs and exhibits at bike shows. To prove powder coating is tough and not brittle when applied correctly, sample panels are tested by impact with a 2lb ball pein hammer. The testing is carried out in front of an audience who are always impressed with our confidence.

Shown: Impact test with 2lb hammer.

Tests adhesion, curing, quality of paint

This simple field test is based on a BS3900-E7. If the domed paint exhibits cracks, it can indicate poor key, dirty metal i.e. grease under the paint, inadequate curing or poor quality powder, which can be brittle. This means the paint is likely to chip during use, the paint will crack under pressure from bolts and paint cracking with the flexing of the frame, all of which will allow moisture to start rusting.

Shown: Impact must be free from cracks.

How much does it cost to powder coat a motorbike frame

To help you estimate prices for your components here are a few examples:

- Standard frame in black gloss: £165 +VAT

- Main stand: £15 +VAT

- Side stand: £12 +VAT

- Headlight shroud: £20 +VAT

- Mudguard: £35 +VAT

- Steel swingarm: £35 +VAT

Please allow an extra £25 for colours. Approximately 100 colours to choose from.

For a comparison between stove enamel and powder coating click here... more